About us

Our main activity is the design and implementation of parts, individual machines and production lines. The first step in the manufacturing of parts is programming, which is done offline with TopSolid7, avoiding incorrect data input and significantly reducing machine downtime. Next, manufacturing is carried out on our CNC milling, grinding and wire and sinker electrical discharge machines, according to modern European technical standards.

CNC milling

► GF Mill S 500

► GF Mill S 500

► DMG MORI DMU 75 monoBlock

► DMG MORI DMU 50

► DMG MORI DMC 650V

► DMG MORI CMX 50U

► MAZAK VARIAXIS I500

► MAZAK VCS 530C

► MAZAK VCS 430A

► OKUMA GENOS M560-V

► HURCO VMX42-i

► HURCO VMX30-i

► BROTHER SPEEDIO R650X1

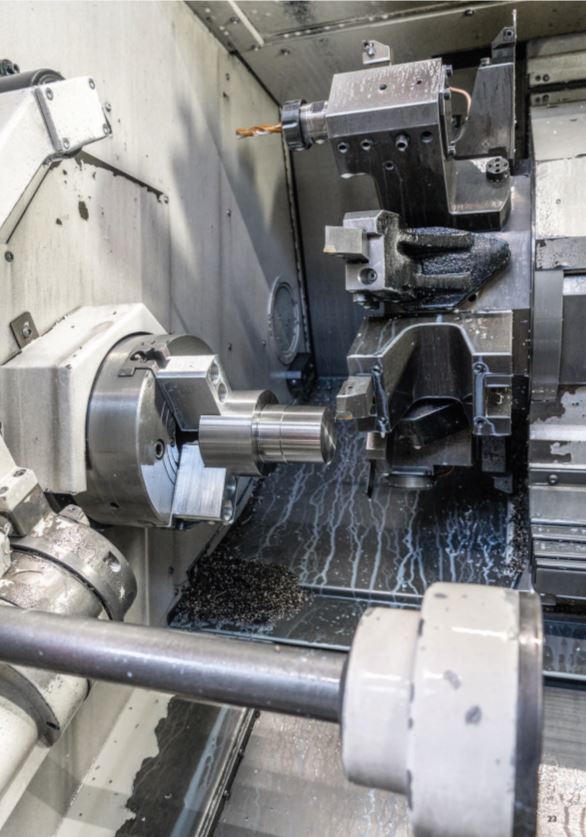

CNC turning

Modern machinery fleet

► MAZAK QTN 200 MSY

► MAZAK QTS 200M

► MAZAK QTS 100S

► OKUMA GENOS L-2000e

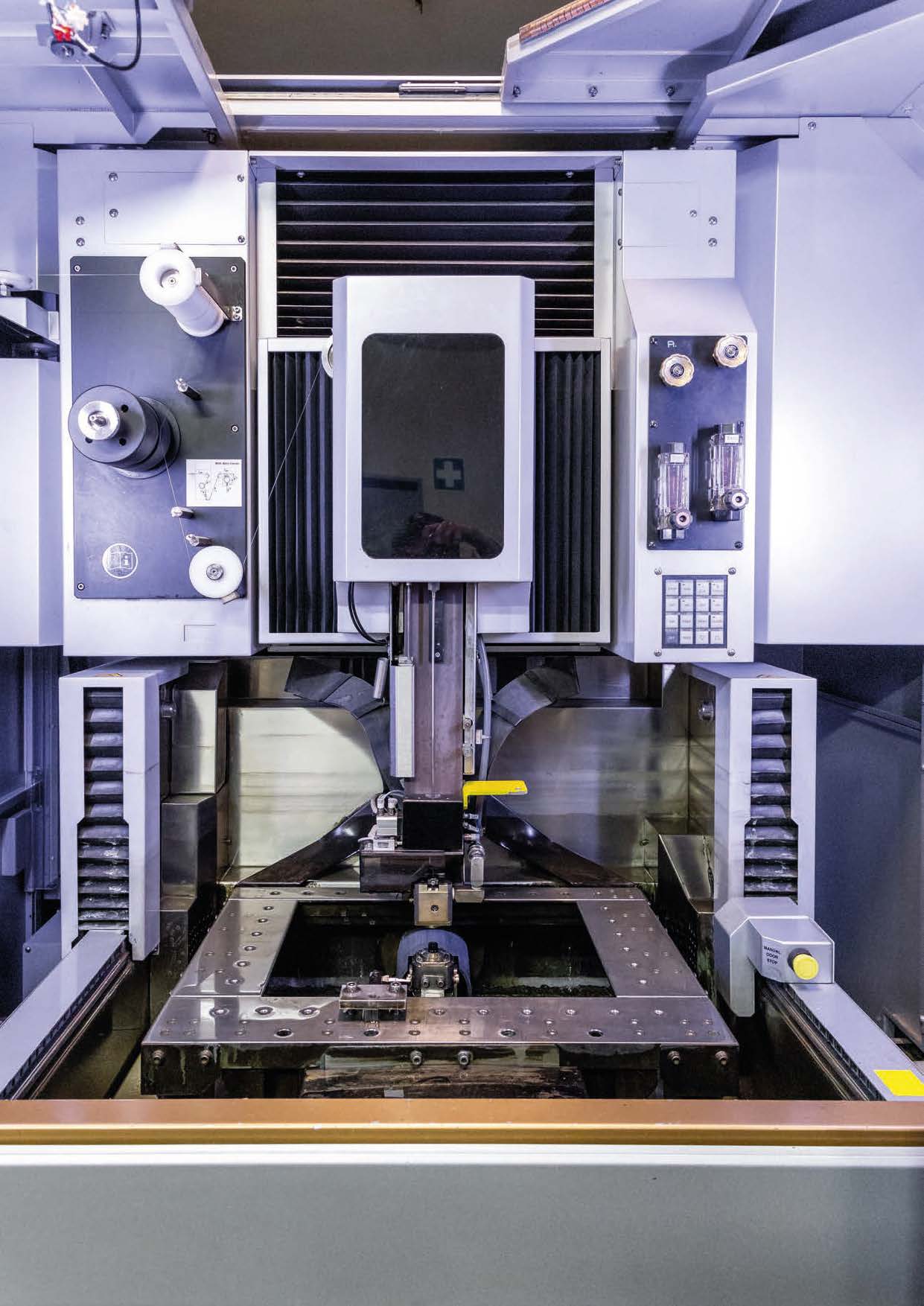

Premium Sodick wire electrical discharge machines:

SODICK ALC 400G Premium Plus

SODICK SLC 400G Premium Plus

SODICK SLC 600G Premium Plus

Sinker electrical discharge machining

Ultra-precise GF machines

AGIE Form 20

AGIE Form E600

Fejlett vezérlés

Easy to use, innovative system with

endless possibilities.

Smooth operation

Thanks to the GF sinker electrical discharge machining

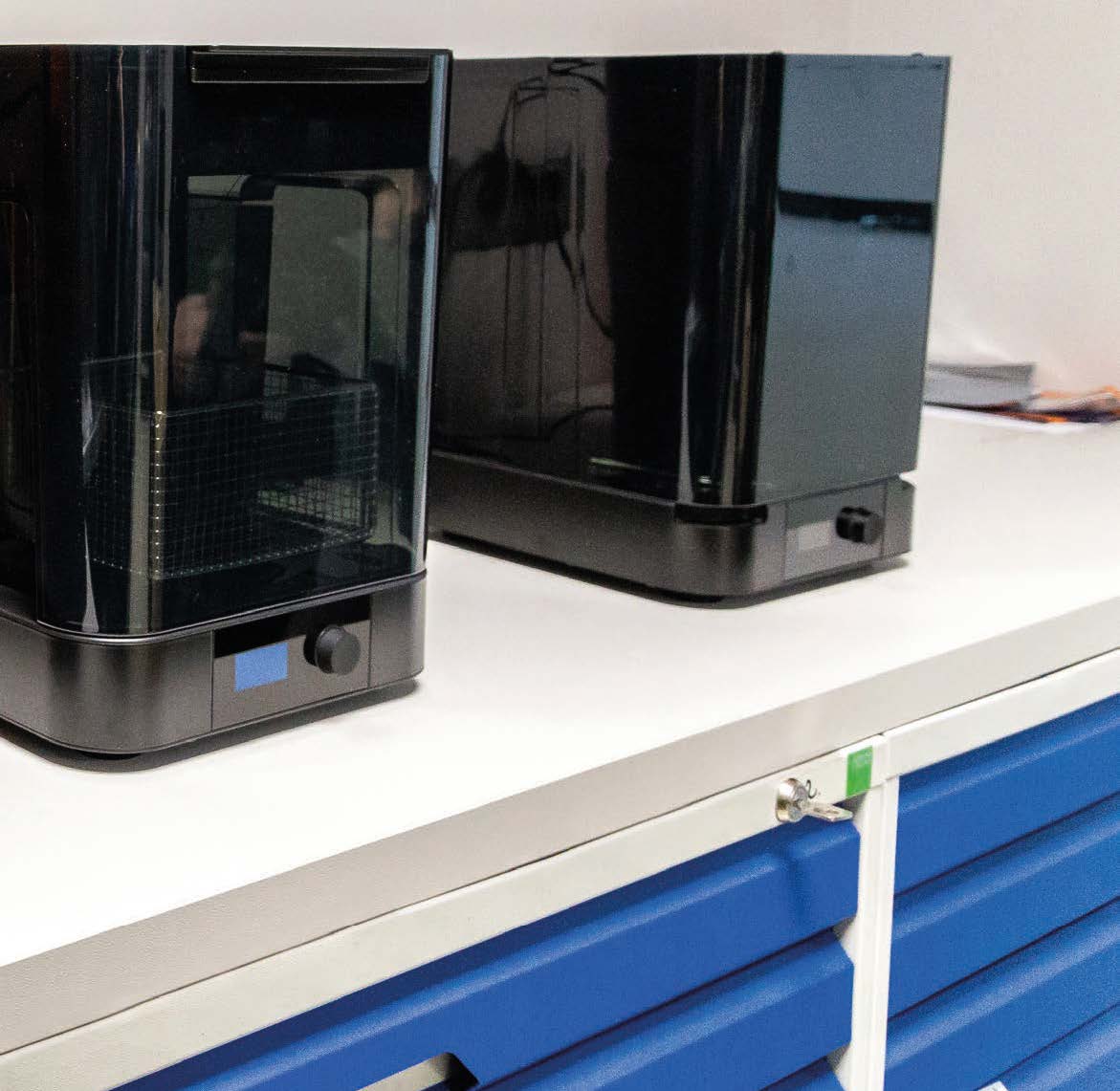

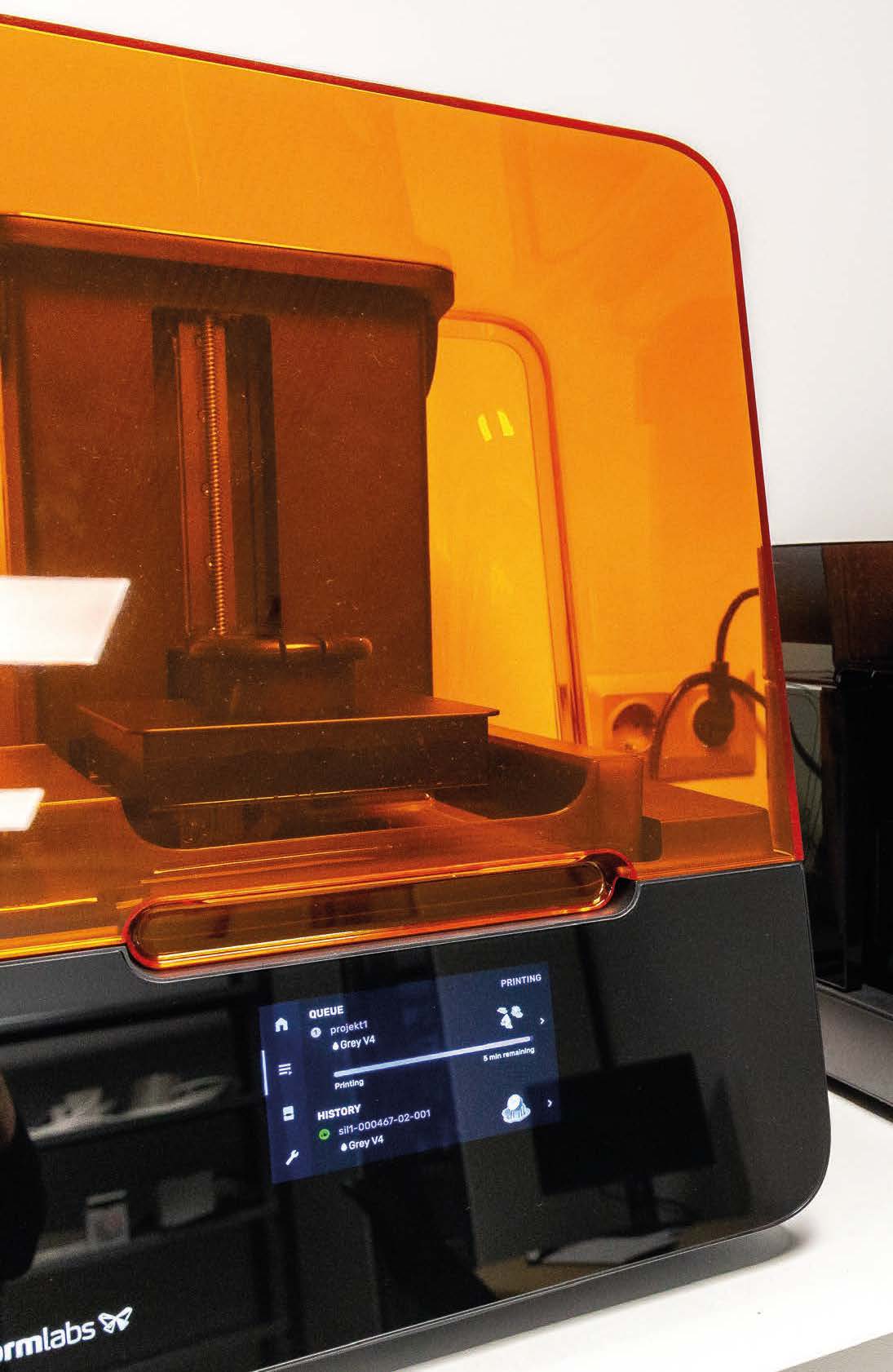

3D printing

Professional LFS (Low Force Stereolithography) technology

► Formlabs Form 3 LFS 3D printer

+ Form Wash rinsing machine

+ Form Cure UV chamber